Technology

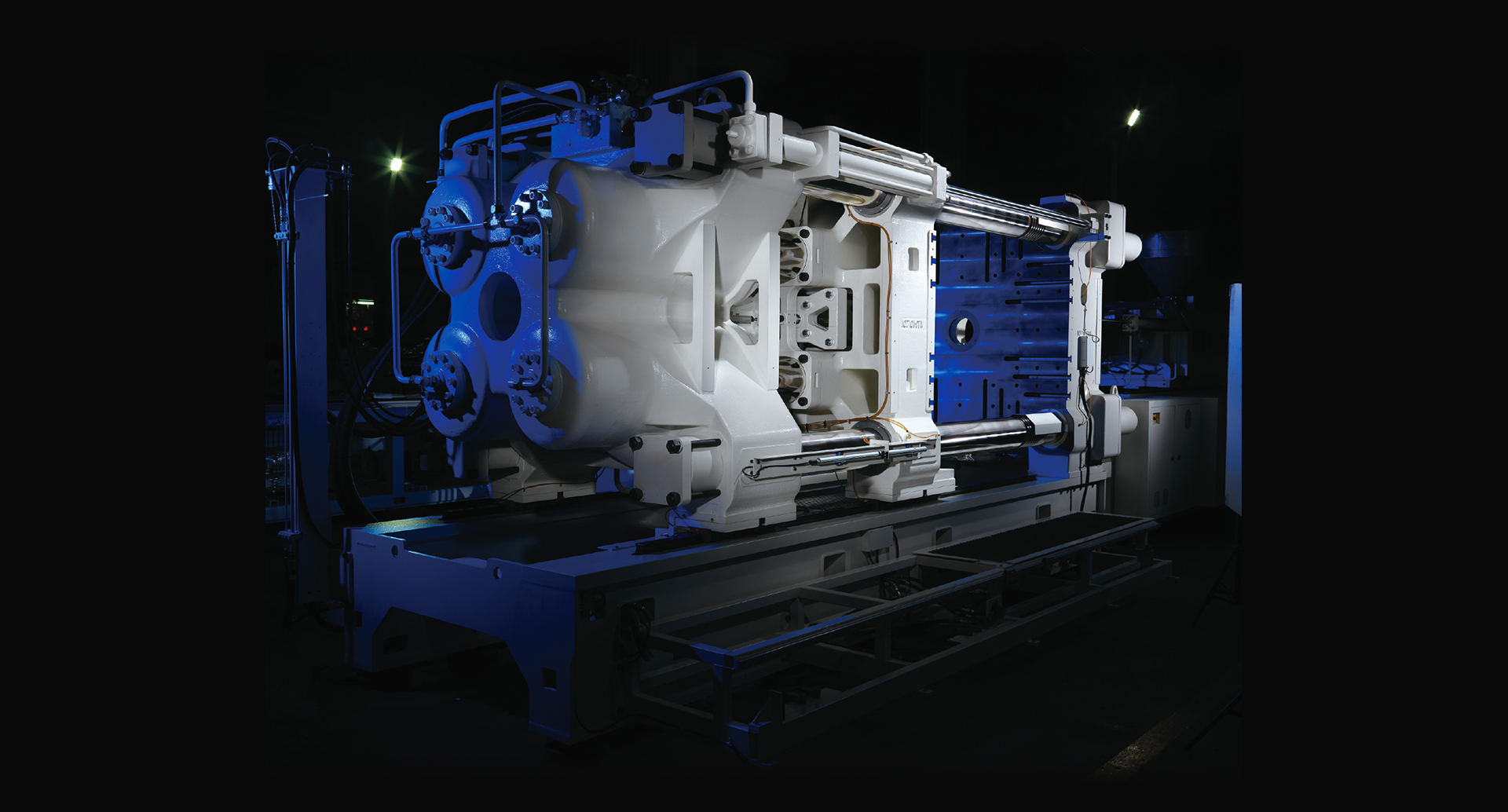

MT II 450t-4000t

II Locking Platen Type

Dual movable locking platen design direct clamping structure

Specifically designed for clamping force above 450 ton. Light sensitive mold closing and opening operation is a comprehensive upgrade of high-precision and high performance results, but also creating a low noise, low power consumption and outstanding performance with low molding cycle.

MT 320t-700t

Four Cylinder Clamping Type

Direct Clamping Structure

MT model with excellent structural rigidity, flexible and accurate, it reduces mechanical wear and power consumption. In response to diverse plastic molding process, the direct clamping system is widely used to meet the technical requirements for precision molding.

ST 35t-270t

Single Cylinder Clamping Type

Direct Clamping Structure

ST model is the advanced design from MT model. It is designed especially for the needs of low-pollution environment. It is widely prefer from the Asian electronics industry, as well as the trust from European and South American customer. Austria KEBA controller

- Database-type controller. Database built-in upgrade functional for variety injection molding machines.

- 200 internal mold datasets, USB access, save the mold changing set up process.

- Clamping, injection and ejector adapt high-precision transducer, which performs accurately driving position.

- Transducer with CAN Bus, SSI interface. (optional)

- Ethernet connection for the host computer. (optional)

- Full closed loop injection with servo valve. (optional)

- Euromap 67(12) robot interface. (optional)

Japan STAR controller

- Japan STAR micro-processing controller, conform to JIS. Choice of three languages can be built, Language available with Chinese, English, Spanish and Japanese.

- 10.4' color LCD screen, quick select button to set the page, simple operation.

- 100 internal mold data sets, memory card slot feature, save the mold changing set up process.

- Clamping, injection and ejector adapt high-precision transducer, which performs accurately driving position.

- Robot interface.

Taiwan Advantech LNC

- 10.4” 全彩高解析度TFT-LCD。

- 支援觸控屏

- 提供開放式人機與PLC編輯軟體,可做二次開發與設計。

- 支援雙色或多色注塑。

- PLC內建多種制程功能模組,快速符合客戶各機型需求。

- 伺服閥閉回路控制。

- 可控制伺服馬達。

- 可搭配雲端監控系統。

- 支援油電複合機。

System Features

- Single unit of Injector design, it is indestructible

- Powerful and speedy injection,and injection driving with short time.

- PID monitor system can precisely control the barrel temperature,that conform to diversified hi-tech molding parts.

- 7 phases of injection pressures、holding pressures and speeds, that can avoid injection scare 、flashing,and decrease stress remain on molding part as well.

- 3 phases of charging speed,it will absolute dissolve material and also accurate volume.

- meter,accurate orientation.

- Logical hydraulic system, it improve hydraulic efficiency and avert from driving force as well.

- Piston type of oil motor, which makes high rotation power.